Trusted Source for Safe Packaging: Pharmaceutical Aluminum Foil Supplier

Introduction

To meet global safety and regulatory standards, choosing a reliable pharmaceutical aluminum foil supplier is essential for manufacturers.

This article explores the importance of pharmaceutical-grade aluminum foil, the features of a reputable supplier, and how these suppliers contribute to the pharmaceutical packaging supply chain. We will also examine how technological advancements are enhancing packaging standards in the industry.

Importance of Pharmaceutical-Grade Foil

It undergoes rigorous testing and complies with strict standards to ensure that it does not react with the medications it encases. The foil must be able to protect against moisture, oxygen, UV light, bacteria, and odors.

Pharmaceutical aluminum foil is commonly used in:

- Blister packs for tablets and capsules

- Strip packs for loose pills

- Sachets for powders and granules

- Lidding foil for bottles or containers

Because these packaging types come in direct contact with the drug, quality and safety are paramount. This is where the role of a dependable pharmaceutical aluminum foil supplier becomes vital.

Characteristics of a Reliable Supplier

A reputable pharmaceutical aluminum foil supplier offers a combination of technical expertise, high-quality products, and adherence to international regulations.

Compliance with Standards

The most important qualification for a supplier in the pharmaceutical space is compliance. A trustworthy supplier should meet standards such as:

- US FDA regulations for direct contact packaging

- EU directives for pharmaceutical applications

- ISO 15378:2017 certification for primary packaging

- GMP (Good Manufacturing Practices) guidelines

Without these certifications, aluminum foil cannot be safely used in pharmaceutical packaging.

See also: The Role of AI Face Swap Technology in Political Campaigns

Material Purity and Coating

Pharmaceutical foil must be of high purity and often comes with coatings such as heat-seal lacquers or primer coatings to ensure it can be securely sealed. These coatings should be non-toxic, odorless, and compatible with medications.

Moisture and Light Barrier

A skilled pharmaceutical aluminum foil supplier will provide technical specifications such as water vapor transmission rate (WVTR) and oxygen transmission rate (OTR) to prove the effectiveness of their materials.

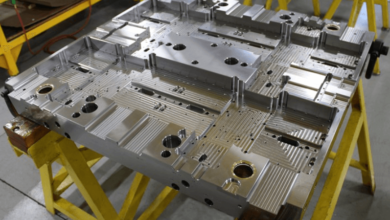

Advanced Production Techniques

To meet increasing global demands and ensure product reliability, modern suppliers use advanced manufacturing technologies. These include:

- Precision rolling mills for uniform thickness

- Automated slitting and cutting lines

- Cleanroom packaging environments

- Multicolor rotogravure or flexographic printing

These innovations not only improve the product quality but also increase customization options. For example, foil can be printed with batch numbers, expiry dates, and branding for pharmaceutical companies.

Customization and Flexibility

A good pharmaceutical aluminum foil supplier offers customized solutions tailored to client needs. This may include:

- Specific foil thickness (e.g., 20 to 30 microns)

- Customized roll widths and core sizes

- Different lacquer types for heat sealing with PVC, PVDC, or cold-forming films

- Printed or unprinted foil options

Suppliers should also be flexible in terms of order quantity—accommodating both large-scale pharmaceutical firms and smaller contract manufacturing organizations.

Logistics and Global Reach

Pharmaceutical companies often operate on strict timelines. A delay in packaging materials can lead to production halts, regulatory issues, and financial loss. Ensure consistent lead times

- Offer global shipping and warehousing support

- Provide real-time order tracking

- Maintain strong communication during the supply process

Established suppliers often have export licenses and experience shipping to regulated markets like the United States, Europe, Australia, and the Middle East.

Environmental Responsibility

Forward-thinking suppliers are adopting eco-friendly practices by:

- Using recyclable aluminum materials

- Minimizing solvent-based coatings

- Investing in solar or clean energy for manufacturing

- Complying with environmental standards like ISO 14001

Partnering with a pharmaceutical aluminum foil supplier that prioritizes environmental stewardship is not only a moral responsibility but also an advantage for companies looking to improve their ESG profiles.

Quality Control and Testing

Before any pharmaceutical foil reaches a client, it should undergo thorough quality checks. Testing parameters typically include:

- Thickness and tensile strength

- Pinholes or surface defects

- Heat-seal strength

- Color and print consistency

- Chemical migration and compatibility tests

Reputable suppliers often provide a Certificate of Analysis (COA) with each batch and may also offer third-party testing reports to validate their product integrity.

Challenges in the Market

Despite the growing demand for pharmaceutical packaging, several challenges remain. These include:

- Regulatory hurdles when exporting to highly regulated markets

- Counterfeit materials from unauthorized or low-quality producers

- Shortage of skilled labor in some regions

Working with a certified and experienced pharmaceutical aluminum foil supplier helps companies mitigate these risks and ensure uninterrupted supply.

Final Thoughts

In a sector as sensitive as pharmaceuticals, there is no room for error when it comes to packaging. A dependable Their ability to provide high-quality, pharmaceutical aluminum foil supplier customized, and compliant foil materials is indispensable for manufacturers across the globe.

Whether you’re producing OTC medicines, prescription drugs, or nutraceuticals, aligning with the right foil supplier is an investment in safety, trust, and long-term success.