Unlocking Precision and Innovation Through Custom Mold Services

In today’s fast-paced manufacturing environment, custom mold services have emerged as a cornerstone of innovation, precision, and product efficiency. As industries continue to evolve with rapidly changing consumer demands, off-the-shelf solutions are no longer sufficient. Companies now require molds that align exactly with their design, functionality, and production requirements — and that’s where custom mold services prove indispensable.

This article explores how custom mold services work, the benefits they provide across industries, and what to consider when choosing the right provider for your business.

What Are Custom Mold Services?

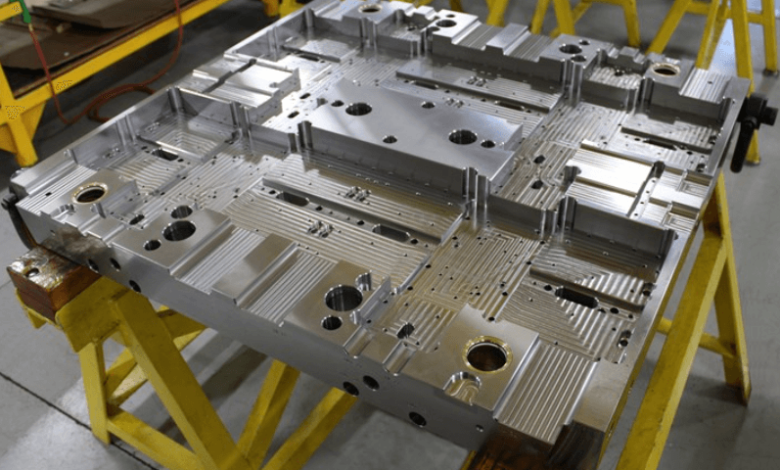

Custom mold services refer to the design, engineering, and manufacturing of molds tailored to specific customer requirements. Unlike standard molds used for generic applications, custom molds are created from scratch to produce parts with unique shapes, tolerances, materials, and surface finishes.

These services are crucial for manufacturing processes like plastic injection molding, metal casting, blow molding, and rubber compression molding. The ability to customize molds gives companies complete control over the product’s geometry, quality, and production scale.

See also: How Technology is Transforming Logistics in Hong Kong

Key Components of Custom Mold Services

The process of delivering high-quality custom mold services involves several coordinated steps:

1. Design Consultation

This phase involves collaboration between the client and engineers to understand product specifications, material requirements, and expected production volumes. CAD (Computer-Aided Design) software is often used to develop the mold geometry.

2. Prototyping

Rapid prototyping using 3D printing or CNC machining helps in visualizing the mold and testing the part before full-scale production begins. This reduces the risk of errors in the final mold.

3. Material Selection

Custom mold services offer a variety of mold base materials such as steel, aluminum, or beryllium-copper depending on production volume, thermal conductivity, and wear resistance requirements.

4. Mold Fabrication

Using advanced machinery like CNC mills, EDM (Electrical Discharge Machining), and grinding tools, mold makers bring the digital design to life with extreme precision.

5. Testing and Validation

Once the mold is completed, trial runs are conducted to verify accuracy, functionality, and dimensional stability. Adjustments are made as necessary before mass production begins.

Advantages of Custom Mold Services

✔️ Tailored Precision

Custom mold services ensure that every detail, from cavity dimensions to surface finish, aligns perfectly with your product requirements. This is critical in industries where even minor discrepancies can result in malfunction or compliance failure.

✔️ Improved Efficiency

Because custom molds are designed specifically for a given part, they often produce components faster and with fewer defects. This reduces cycle time and increases production output.

✔️ Enhanced Product Performance

With the ability to include features like undercuts, texture finishes, and thin walls, custom molds support the production of parts that are both functional and visually appealing.

✔️ Cost Savings Over Time

Though the initial cost of custom mold services may be higher than using generic molds, the long-term return on investment (ROI) is better due to increased accuracy, reduced material waste, and minimized product rework.

✔️ Competitive Advantage

Having access to unique parts designed specifically for your application can differentiate your brand in the marketplace. This is particularly valuable in highly competitive industries such as electronics, medical devices, and automotive components.

Industries Benefiting from Custom Mold Services

🏭 Automotive

From engine covers to dashboard panels, the automotive industry depends heavily on custom mold services to manufacture complex components with stringent tolerance requirements.

💊 Medical Devices

Medical-grade plastic and silicone parts require custom molds that can meet hygiene, biocompatibility, and dimensional accuracy standards.

📱 Consumer Electronics

Manufacturers of smartphones, laptops, and wearables use custom mold services to ensure compact form factors, aesthetic finishes, and functional integration.

🚿 Home Appliances

Custom mold services enable manufacturers to produce ergonomic and attractive housings, buttons, and internal parts for everyday appliances.

🚀 Aerospace

Precision and lightweight parts are vital in aerospace, and custom molds allow for the development of high-performance components using specialized materials.

Common Types of Custom Mold Services

🔹 Plastic Injection Molds

Used to manufacture a wide range of thermoplastic and thermosetting plastic components in high volume.

🔹 Compression Molds

Ideal for rubber and silicone parts that require high heat and pressure to take form.

🔹 Die Casting Molds

These are used for forming complex metal parts with tight tolerances, particularly in automotive and electronics sectors.

🔹 Blow Molds

Commonly used for producing hollow plastic parts like bottles, containers, and tanks.

Choosing the Right Provider for Custom Mold Services

Not all providers offer the same level of quality or service. Here’s what to look for when selecting a partner for your custom mold services:

✅ Experience & Technical Expertise

A proven track record in mold design and manufacturing is essential. Ask for case studies or client references in your industry.

✅ Advanced Technology

Ensure the provider uses up-to-date machinery such as high-speed CNC, EDM machines, and simulation software to deliver precision and repeatability.

✅ Customization Flexibility

Look for services that can handle small to large production runs, diverse mold materials, and complex geometries.

✅ Quality Control Systems

A reliable provider will conduct thorough inspections, including mold flow analysis, dimensional checks, and material certifications.

✅ After-Sales Support

Post-delivery services like mold maintenance, refurbishing, and adjustments ensure the long-term success of your production.

Emerging Trends in Custom Mold Services

🔄 Rapid Mold Prototyping

With additive manufacturing becoming more advanced, mold prototyping is quicker and more cost-effective than ever, allowing for faster product development cycles.

🤖 Smart Mold Technology

Integration of sensors and IoT into molds provides real-time feedback on temperature, pressure, and wear, enhancing productivity and longevity.

🌿 Sustainable Mold Materials

Eco-conscious companies are now demanding molds made from recyclable or energy-efficient materials to reduce environmental impact.

🌍 Global Outsourcing

Many companies now outsource custom mold services to specialized regions such as China or Eastern Europe to benefit from cost efficiencies and skilled labor.

Final Thoughts

Custom mold services are no longer a luxury but a necessity for businesses striving to meet exacting standards in performance, durability, and design. Whether you’re producing intricate electronic enclosures or robust industrial components, investing in the right mold solution can streamline your operations and give you a distinct edge in your market.

As technologies evolve and customization becomes the new normal, having a mold that is tailored to your specific application is not just beneficial — it’s essential.