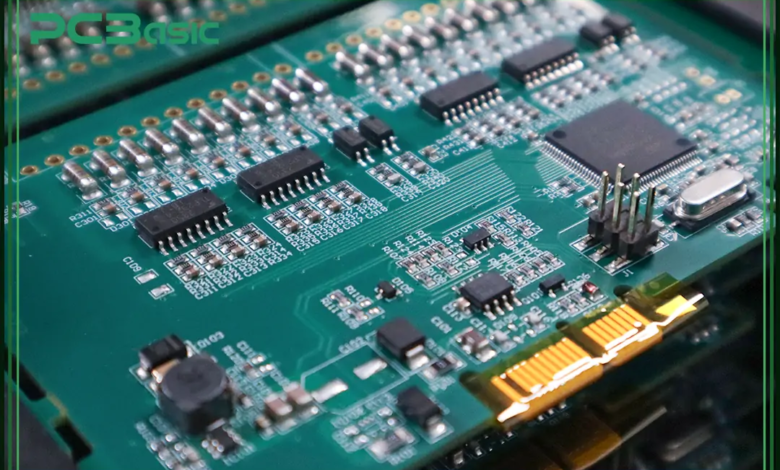

How to Estimate Printed Circuit Board Assembly Costs with the PCBasic PCB Assembly Cost Calculator

When planning an electronics project, controlling the printed circuit board assembly (PCBA) budget is just as important as designing the board itself. Costs can vary based on board complexity, components, and testing needs. That’s why the PCBasic PCB Assembly Cost Calculator is a powerful tool for achieving faster, more accurate project planning.

If you want to eliminate guesswork and take full control over your production costs, the PCBasic PCB Assembly Cost Calculator is the best place to start.

Why Printed Circuit Board Assembly Cost Estimation Matters

Printed circuit board assembly involves several key steps: applying solder paste, placing components, reflow or wave soldering, inspection, and testing. Each stage carries specific labor, material, and time costs.

Without a detailed estimate, projects may suffer from unexpected expenses, design changes, or production delays.

Accurate cost estimation with the PCBasic PCB Assembly Cost Calculator allows you to:

- Build reliable budgets

- Prevent costly mistakes early

- Optimize designs for manufacturability

- Streamline supplier communications

In short, good cost planning leads to faster launches and higher profit margins.

How the PCBasic PCB Assembly Cost Calculator Works

Using the PCBasic PCB Assembly Cost Calculator is straightforward:

1649. Enter PCB Details: Input board dimensions, number of layers, surface finish, and material type.

1650. Add Assembly Information: Provide component quantities, special component handling (such as BGA, QFN), and placement technologies (SMT, THT, or mixed).

1651. Select Testing Requirements: Choose between basic inspections like AOI or advanced methods like flying probe testing.

1652. Receive Instant Quote: Get a real-time, detailed cost estimate for your printed circuit board assembly

The calculator immediately adjusts estimates based on your input, giving you full flexibility to explore different options.

Main Factors Influencing Printed Circuit Board Assembly Cost

When using the PCBasic PCB Assembly Cost Calculator, it’s important to understand the factors that impact the final quote:

- Board Size and Layer Count: Larger, multi-layer boards cost more to produce and assemble.

- Component Complexity: Small-pitch, high-pin-count, and delicate parts increase assembly precision and inspection time.

- Assembly Volume: Higher volumes generally reduce the per-unit cost, while small batches have a higher setup cost impact.

- Lead Times: Standard production is more economical; expedited timelines add premium fees.

- Testing and Quality Assurance: Extra inspections, such as X-ray or functional testing, add costs but ensure reliability.

The PCBasic PCB Assembly Cost Calculator accounts for all these elements to give you a comprehensive overview.

Why Choose PCBasic for Your Printed Circuit Board Assembly Projects?

PCBasic offers complete, high-quality printed circuit board assembly services with a focus on flexibility, reliability, and customer satisfaction.

With nine advanced SMT lines, a team of skilled engineers, and years of industry experience, PCBasic delivers PCBA solutions that meet the most demanding specifications.

Our PCBasic PCB Assembly Cost Calculator is part of our commitment to transparency and excellence—giving you the tools to succeed from the very first step of your project.

Take control of your electronics production with the PCBasic PCB Assembly Cost Calculator—the smart way to plan your printed circuit board assembly budget.